1. Mechanical Principles Behind 4 Wings Bearing U-Joints

4 Wings Bearing U-Joints are pivotal components in mechanical power transmission systems, renowned for their ability to transfer torque across non-aligned shafts. Understanding their mechanical principles is crucial for optimizing their performance and longevity in diverse industrial applications.

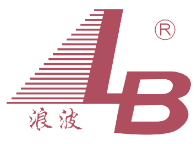

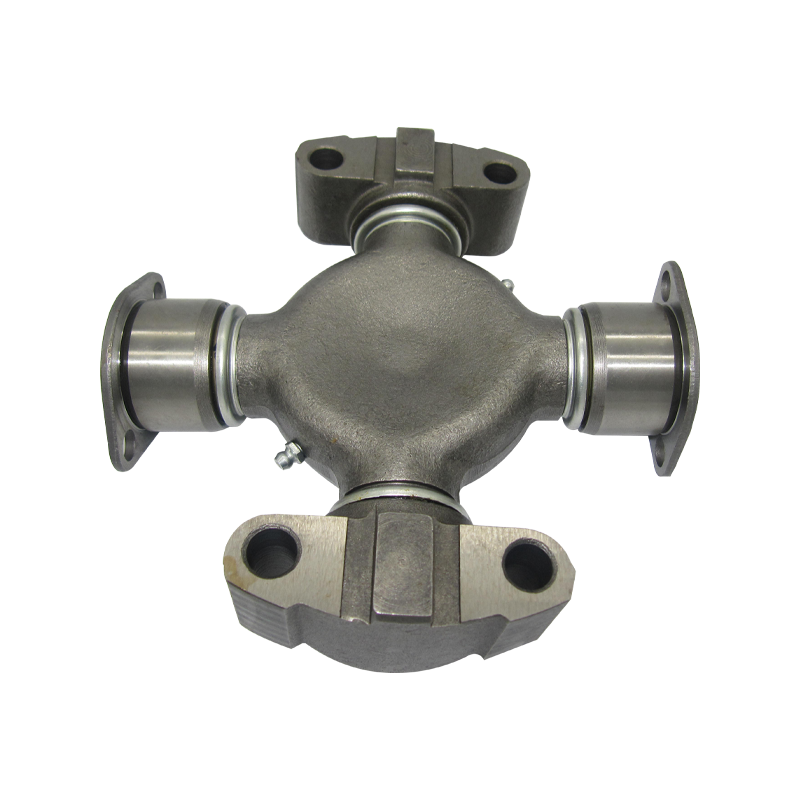

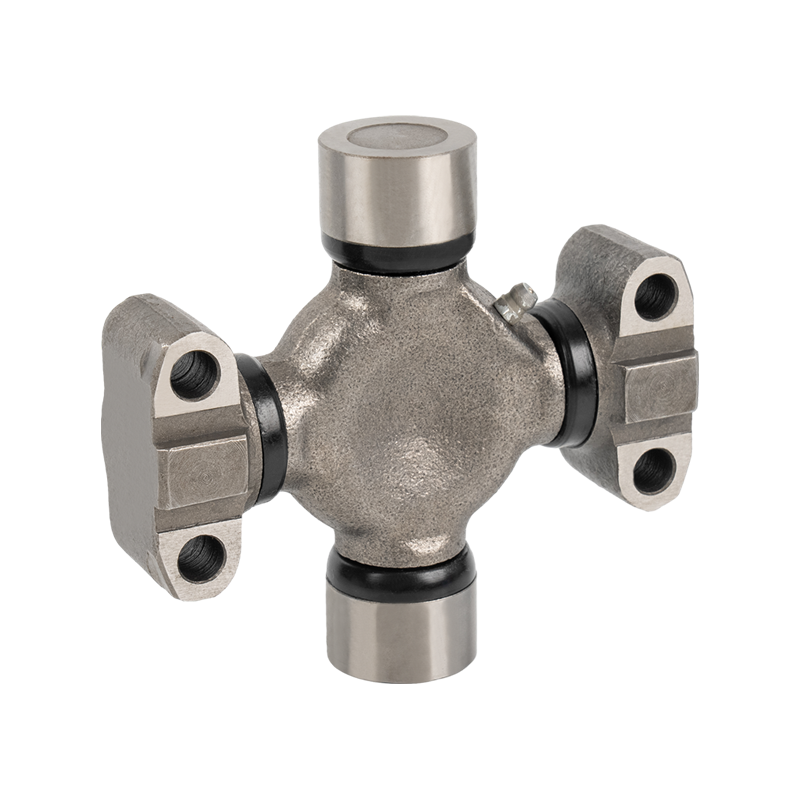

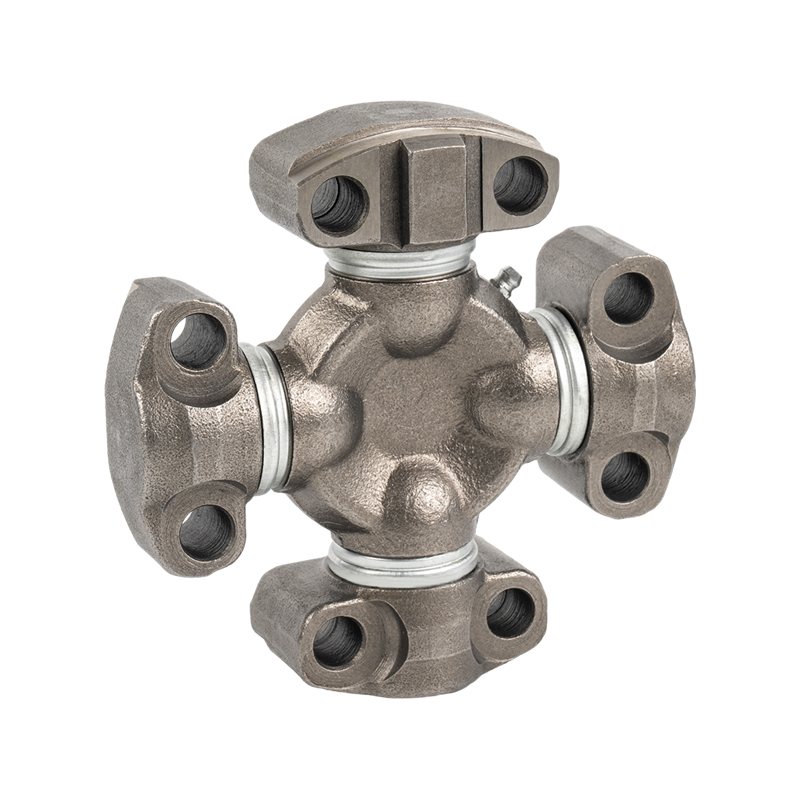

a)Torque Transmission Mechanism: At its core, the primary function of a 4 Wings Bearing U-Joint is to transmit torque between two shafts that are not in perfect alignment. This is achieved through a series of bearings arranged in a cross-like configuration, with four wings or trunnions that connect the yokes of the shafts. As the input shaft rotates, it imparts angular motion to the cross, which in turn rotates the output shaft, allowing torque to be transmitted efficiently even when the shafts are at an angle.

b)Angular Misalignment Capability: One of the key advantages of 4 Wings Bearing U-Joints is their ability to accommodate significant angular misalignments between shafts, which can occur due to mounting constraints, thermal expansion, or dynamic operating conditions. The design of the bearings and trunnions allows for smooth operation even when the shafts are not perfectly aligned, thereby reducing wear and extending the life of the joints.

c)Load Capacity and Stress Distribution: Effective torque transmission in 4 Wings Bearing U-Joints depends on the load capacity of the bearings and the stress distribution across the joint under various operating conditions. Engineers must consider factors such as shaft speed, torque magnitude, and operational environment to ensure the U-joints can withstand the required loads without premature failure. Proper lubrication and maintenance play crucial roles in optimizing load capacity and minimizing wear.

d)Design Variations and Performance Factors: The performance of 4 Wings Bearing U-Joints can vary based on design factors such as bearing type (needle bearing vs. plain bearing), material selection (steel alloys, stainless steel, etc.), and the presence of seals or dust caps to protect against contamination. Each design variation offers distinct advantages in terms of durability, friction reduction, and operational efficiency, depending on the specific application requirements.

e)Dynamic Balancing and Vibration Control: Maintaining dynamic balance is essential for smooth operation and extended service life of 4 Wings Bearing U-Joints. Imbalances can lead to increased vibration, accelerated wear on bearings, and potential failure of the joint. Proper installation and periodic balancing procedures are critical to minimize vibration and ensure reliable performance over time.

2. Maintenance and Lubrication Practices for 4 Wings Bearing U-Joints

Effective maintenance and proper lubrication are essential for maximizing the performance, longevity, and reliability of 4 Wings Bearing U-Joints in mechanical power transmission systems.

a)Importance of Regular Inspection: Regular inspection forms the cornerstone of proactive maintenance for 4 Wings Bearing U-Joints. Inspections should include checking for signs of wear, such as excessive play or corrosion, inspecting seals and dust caps for integrity, and ensuring proper alignment of shafts. Visual inspections should be complemented by periodic measurements of joint clearances and bearing wear to detect early signs of deterioration.

b)Lubrication Requirements: Proper lubrication is critical to reducing friction, dissipating heat, and preventing premature wear in 4 Wings Bearing U-Joints. The type and quantity of lubricant used depend on factors such as operating temperature, load conditions, and environmental factors. Manufacturers often specify lubrication intervals and recommend suitable lubricants, such as high-performance grease or oil formulations, to ensure optimal joint performance.

c)Lubrication Methods: Several methods can be employed to ensure effective lubrication of 4 Wings Bearing U-Joints. Manual lubrication involves applying grease or oil directly to accessible fittings or points on the joint assembly. Automatic lubrication systems offer a more continuous and controlled application of lubricant, ensuring consistent coverage and minimizing human error. The selection of lubrication method depends on accessibility, operational complexity, and maintenance strategy preferences.

d)Seal and Dust Cap Maintenance: Seals and dust caps play a crucial role in protecting 4 Wings Bearing U-Joints from contaminants such as dust, moisture, and debris. Inspect seals regularly for signs of wear or damage and replace them promptly to prevent ingress of contaminants that can accelerate wear and compromise joint performance. Properly maintained seals and dust caps contribute to extending the service life of U-joints and reducing the frequency of maintenance interventions.

e)Temperature and Environmental Considerations: Operating temperature variations and environmental conditions can affect the performance and lifespan of lubricants in 4 Wings Bearing U-Joints. Extreme temperatures can alter the viscosity of lubricants, potentially leading to inadequate lubrication and increased friction. Selecting lubricants with appropriate viscosity ratings for specific temperature ranges and ensuring adequate protection against moisture and chemical exposure are essential considerations for maintaining optimal joint performance.